Pre Assembled Clip

Pre Assembled Clip

Slip Clip: S Clip

Product Application

Product Application

VertiClip® SLD connects the interior drywall studs at the head condition (top of wall) to the deck or primary frame while allowing for a total vertical deflection of up to 1½” (¾” up and ¾” down). VertiClip’s unique design provides both an anti-friction and anti-seizure connection between the clip and the stud web surface thereby preventing a transfer of vertical forces into drywall partition wall framing, which is not designed to support axial loads. VertiClip SLD is a component in VertiTrack® VTD, TSN’s pre-assembled deflection track. Allowable loads are based on use of two #8 screws for attachment to stud (provided by TSN).

Material Composition

ASTM A653/A653M, Grade 50 (340), 50ksi (340 MPa) minimum yield strength, 65ksi (450 MPa) minimum tensile strength, G- 60 (Z180) hot-dipped galvanized coating. Material thickness = 33mil (20 gauge, 0.0346” design thickness).

The attachment of VertiClip to the primary structure may be made with a PAF and is dependent upon the base material (steel or concrete) and the design configuration.

|

An ICC-ES Evaluation Report for VertiClip SLD600 is available. |

|

|

A Los Angeles Research Report for VertiClip SLD, SL, SLB, SLS, and SLT Series is available. Refer to LARR #25631. |

Note:

- Fasten within ¾” from the angle heel (centerline of the 1½” leg) to minimize eccentric load transfer.

- Guide holes for attachment to structure are .172” in diameter, and are standard for SLD362 and SLD600.

- Deflection requirements greater than ¾” (up and down) are available.

VertiClip® SLD series is designed to support horizontal loads and should not be used in axial-load-bearing wall construction.

The VertiTrack® deflection track system is used to connect the interior studs at head of wall while allowing for a vertical deflection of the structure up to 1½” (¾” up and ¾” down). VertiClip’s® unique design provides both an anti-friction and anti-seizure connection between the clip and the stud web surface, thereby preventing a transfer of vertical forces into drywall partition framing, which is not designed to support axial loads. VertiTrack VTD is composed of VertiClip SLD pre-attached to a top runner track at pre-designated stud spacing.

Material Composition

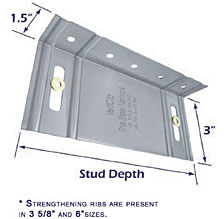

Track and clip material: ASTM A653/A653M, Grade 50 (340), 50ksi (340 MPa) minimum yield strength, 65ksi (450  MPa) minimum tensile strength, (clip); 33ksi (230MPa) minimum yield strength, 45ksi (310 MPa) minimum tensile strength (track); G-60 (Z180) hot-dipped galvanized coating (clip & track). Track leg length = 1½”. Track and clip material thickness = 33mil (20 gauge, 0.0346” design thickness). The attachment of VertiClip to the primary structure may be made with a PAF and is dependent upon the base material (steel or concrete) and the design configuration.

MPa) minimum tensile strength, (clip); 33ksi (230MPa) minimum yield strength, 45ksi (310 MPa) minimum tensile strength (track); G-60 (Z180) hot-dipped galvanized coating (clip & track). Track leg length = 1½”. Track and clip material thickness = 33mil (20 gauge, 0.0346” design thickness). The attachment of VertiClip to the primary structure may be made with a PAF and is dependent upon the base material (steel or concrete) and the design configuration.

Note:

- Fasten within ¾” from the angle heel (centerline of the 1½” leg) to minimize eccentric load transfer.

- Fasten through each VertiClip SLD to structure.

VertiTrack VTD is designed to support horizontal loads, and should not be used in axial-load-bearing walls. VertiTrack VTD is assembled with VertiClip SLD pre-attached at 16” o.c. and 24” o.c. Custom spacing is also available. Screws and step bushings are provided for attachment of VertiClip to the stud web.

Three Legged Dog – 16 Ga.

- ASTM A653 Galvinized Steel

- Standard protective coating equal or superior to ASTM A653 coating designation G-60 or A-60

- 16 gauge

- UL Fire Resistance Directory (Control# 6CA8, File# R20831)

Approved UL Joint Systems for the Three Legged Dog

Download ![]()

Posi Clip – 20 & 16 GA by Fire Frak

Redi Clip

Download Information ![]()

The Fire Trak Slip Clip allows you to positively attach a steel stud to the Fire Trak ceiling runner while still allowing it to move vertically in the track. The Slip Clip can also be used with a deep leg track in non-rated assemblies as shown below.

Sold in quantities of 500 clips

No freight charge on clip orders sent by UPS Ground

$15.00 freight charge per 500 clips on orders sent by UPS 3 day Select

All freight options quoted on an order by order basis

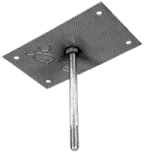

Deflection Post

This new product called the D-Flexion Post solves a long-standing problem in a simple, direct way. The problem has been in figuring out how to allow for vertical deflection in a curved wall.

D-Flexion Post is made to work hand in hand with Flex-C Trac, the innovative product that has saved so many framers the headaches that come with framing curved walls.

To build a vertically deflecting curved wall with D-Flexion Post:

First, Form and secure Flex-C Trac in the desired curve. Second, Insert the D-Flexion Post into a pivot hole ofFlex-C Trac. Use as many Posts as needed for the desired lateral strength of the wall. Third, After confirming your layout, anchor D-Flexion Post to the top deck using the pre-punched holes in the base plate. Last, install the wall studs.

D-Flexion Post is made of galvanized steel and will allow 4 inches of total vertical movement.

D-Flexion Post – 16 Ga.

Base Plate:

- ASTM A653, galvanized steel

- Standard protective coating equal or superior to ASTM A653 coating designation G-40 or A-40

- Dimensions: 3.375″ x 5.75″, .060″ thick

Post:

- ASTM A307, Grade A, zinc plated steel bolt

- Dimensions: 5″ length, .375″ diameter